OreSense® closes the gap between data capture and decision-making.

Mining operations need fast, reliable orebody insights to drive better decisions – but traditional methods are slow, expensive, and often delayed by lab analysis. OreSense® changes that by delivering real-time, high-resolution ore characterisation in under 15 minutes.

Where Plotlogic adds value

Unlike traditional methods that can take hours or even days, OreSense® captures, processes, and delivers high-resolution orebody data in less than 15 minutes.

Measure

- Mounted on a Light Vehicle

- Simple operation

- Scanning time from 3 to 15 minutes

- Semi-automated scanning functionality

Process

- Data delivered in less than 15 minutes

- Automated processing and data cleansing

Connect

- Data stored in cloud

- Automatic upload on network connection

- Automated data management

- Remote access for service and support

View

- Data accessed through dedicated web portal

- Search and view scans/faces

- Define regions of interest, cut off grades

- Remote access for service and support

OreSense® brings precision to mining – like clustering every dart near the bullseye.

Track ore-waste boundaries with accuracy, seamlessly integrated into current processes, improving confidence at every step.

Spot dilution early, guiding proactive waste management to protect value, without complicating decisions.

Boost plant throughput by improving material handleability using your existing infrastructure.

Reduce rehandle by guiding machine movement with near real-time orebody data, aligning with operator routines.

Unlock more from trusted assets, lifting productivity without new equipment.

Enhance ore recovery by consistently pinpointing high-value zones, driving confident, precise decisions.

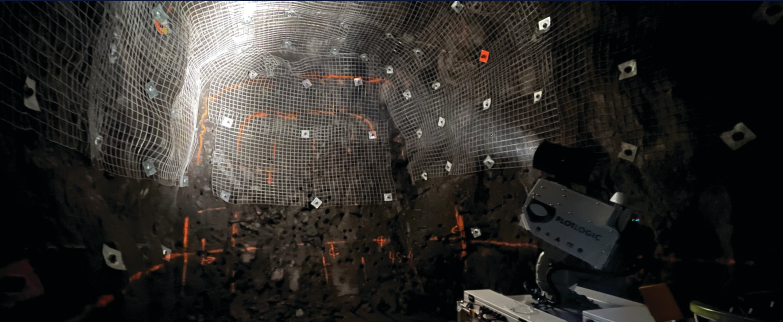

Know what you’re mining as you mine it.

Whether it’s identifying exactly what should be mined, tracking material movement, or ensuring alignment with the mine plan, OreSense® gives you immediate clarity underground and on the surface.

Using advanced AI and automated processing, the system delivers pixel-level classification of material in real time, helping teams make informed decisions on the spot.

Quick Reference Guides

Need answers fast? Our Quick Reference Guides give you clear, no-fuss explanations to our most commonly asked questions.

Learn more OreSense® works and where it can add value to your operations.

DOES ORESENSE® PENETRATE THE GROUND?

OreSense® has redefined how mining operations see their orebody. OreSense® complements traditional methods

HOW ACCURATE IS ORESENSE®?

Plotlogic’s, OreSense® is an Australian designed, purpose-built Mine Imaging Scanner featuring a proprietary sensor stack and AI processing.

WHAT CAN ORESENSE® DETECT?

OreSense® by Plotlogic was designed for broad applicability across the mining industry.

Are you interested in learning how Plotlogic can help you?

Reach out to explore how our technology can support your projects or discuss collaboration opportunities.